Don’t overfill

Understandably all bladder tanks have a maximum filling point which must be adhered to or risk a big clean-up. Best practice is to have a level indicator to warn when the bladder is getting close to maximum capacity so you can stop pumping into it or divert effluent into a secondary bladder or alternative storage.

Empty Annually

It’s important to empty the bladder tank completely at least once a year to flush out any solids. Make sure the top vents of the bladder are clear while emptying.

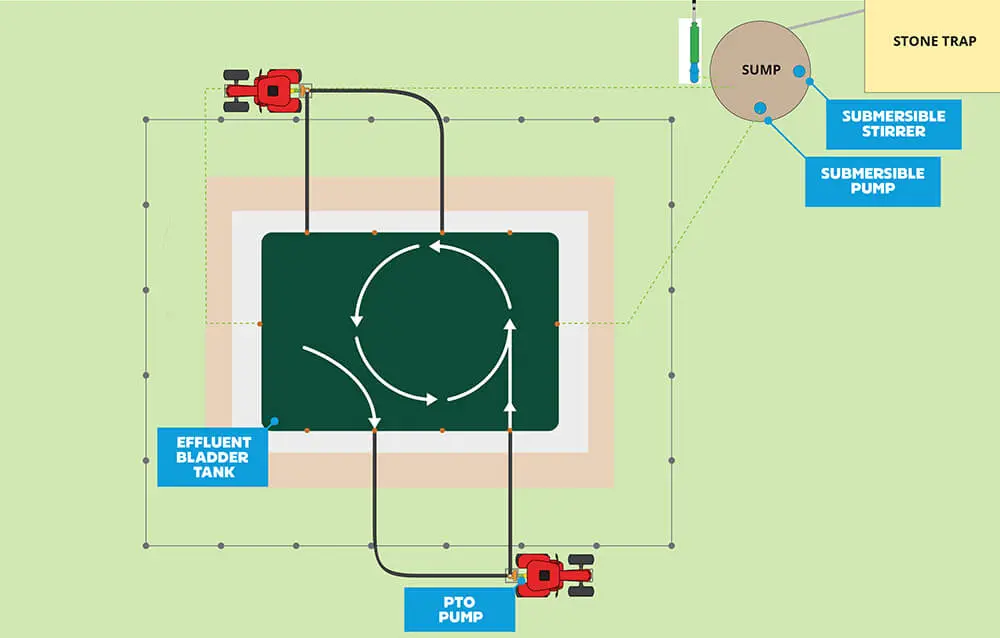

Stir Regularly

Keeping the effluent well mixed is imperative to ensure solids do not settle at the bottom or for crust and weeds to form on top. It also helps to keep the biological activity alive, providing higher nutrient value. Watch the video How to Stir a Bladder Tank here….

Keep It Fenced

Despite bladder tanks being a closed effluent storage solution, and safer with no risk of people falling in, it is still recommended they are fenced off. Fencing reduces the risk of livestock, children, or anyone else tampering with the valves which could have undesirable consequences.

Maintenance Checks

Although bladder tanks designed for storing effluent are almost indestructible, it’s always advisable to check them for any signs of wear or damage every now and again. Repair kits are available should you notice anything that needs attending to.

When selecting a bladder tank for storing effluent it is important to choose one built for purpose. Bladder tanks designed for storing water will typically use a thinner material and not include a lot of the durability features required to store effluent, resulting in higher maintenance requirements.