If this sounds like you, and all you need is more effluent storage – keep reading!

Effluent Sumps

Contrary to popular belief, an above ground tank is not the only solution, and also not always the best solution to extra sump storage. Below are 3 possible solutions, and as always, if you’d like recommendations for your specific situation, talk to a Nevada specialist for a FREE assessment.

Pumping Recommendations

Once you’ve given the effluent sump the tick of approval, it’s time to look at how the sump will fit into your overall effluent management system.

Sumps were designed to be the focal point for storing and pumping effluent out to pasture. Logically when more storage is required, the thought is that the sump will remain the focal point for pumping, and the additional storage will just hold the overflow. However this is not what we would recommend in most cases. Where possible it is best to pump from one main site. Pumping from one main effluent storage area will make the system far easier to manage, and lower your overall costs, not to mention simplify the effluent compliance process.

Sump Assessment

When it gets to the point you’re needing additional effluent storage for your sump, the first thing to check is the efficiency of your sump.

A good sump should be able to hold at least 3 days worth of effluent to be efficient. If your sump isn’t up to scratch, for cost and productivity purposes, you may consider replacing it.

Sump Storage Solutions

Solution 1 – Effluent Pond As #1

If gravity is on your side, to maximise your effluent management effliciency, your best option may be to ignore the fact you already have a sump with a good pumping system, and instead direct all your effluent into a lined pond placed below the current sump. Where possible, the sump could then be converted into a stone trap, and the pump can possibly be re-purposed.

The benefits of using the new effluent pond as your focal point for storage and pumping are:

- Far easier management.

- Eliminates the risk of your pumping chamber becoming inundated.

- Lower cost per cubic metre of storage.

- No risk of overflow.

- Much easier to maintain council compliance.

- We recommend lining your pond with a HDPE liner as they are compliant with environmental and regional regulations, and are designed to last for over 100 years. Contrary to popular belief, they are also the most cost effective option.

Whether re-purposing your sump pump, or going for a new one, for operator safety and service efficiency a Nevada PondBoom™ is recommended for retrieving your effluent pump for servicing or maintenance.

For this set up you may also need to consider a slurry stirrer (PTO or Electric), and also the best way of spreading. We’d recommend using either a slurry tanker or drag hose system with RainWave™.

Solution 2 – Effluent Pond As #2

If you still want to have your sump as the main source of pumping and irrigation, a solution to consider would be to create some kind of storage at the end of your irrigation system for the overflow. Excess effluent that is pumped through to this additional storage area can then be spread over the pasture that is untouched by the sump irrigation system.

Ideally this storage would be a lined pond (as the most cost efficient option), but it could also be a steel storage tank if a pond was not an option.

Benefits of this solution are:

- Increase your spreading area.

- Easier management.

- Eliminates the risk of your pumping chamber becoming inundated.

- Lower cost per cubic metre of storage.

- Less risk of overflow.

- Depending on the type of storage at the end of the system, you may also need to consider how the slurry will be stirred, pumped and spread. You can either get a contractor in every now and again to do it for you, or you can save some $$$ and DIY it!

Ponds are the easier option for stirring, as most can be easily mixed by hooking up a PTO stirrer to your tractor (or use an electric stirrer if it’s an option). For hard to reach ponds, or above ground tanks, PTO stirrers can have an extension fitted. Alternatively for tanks there is a through the wall option.

As for spreading, we’d recommend either a drag hose system to spread straight from the back of your tractor, or heading for a slurry tanker.

Solution 3 – Above Ground Tank

If gravity is not on your side, an above ground tank may be your best option. Above ground effluent tanks are also best suited for:

- Swampy & high water table sites where it’s not possible to dig a pond

- High rainfall areas, where a pond would be prone to overflow

- Sites close to residential properties

In this case we would recommend a steel storage tank, due to their longevity and reliability. In selecting a reliable tank, the things to look for are:

- Engineering certification

- Warranty

- Building code compliance

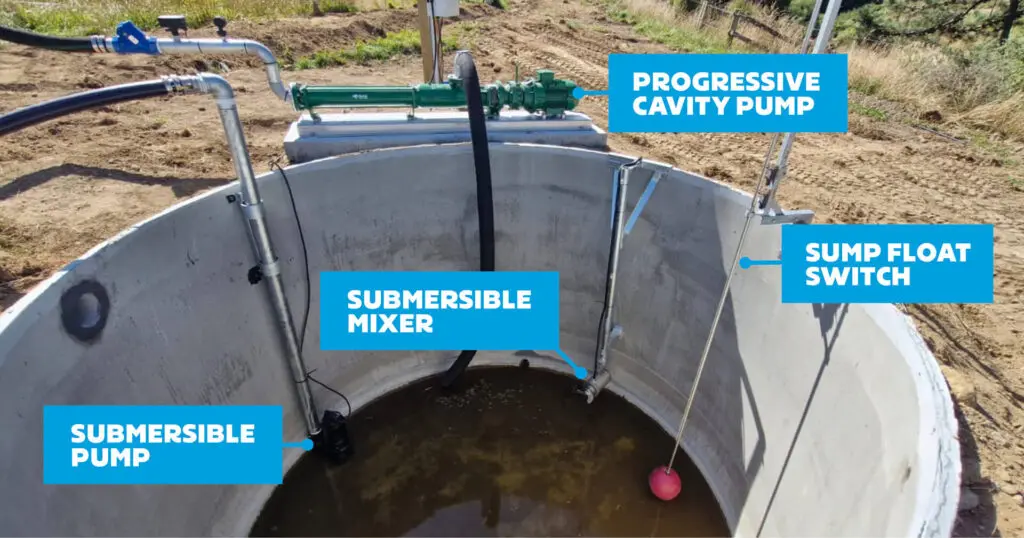

As for pumping, you’ll need to be set up with a high volume transfer pump for transferring the effluent from sump to tank and vice versa. It’s important to choose a quality pump that will handle large volumes, as the system needs to maintain a stready flow so not to overload the sump. As a precaution, it is also recommended to have a backup PTO tractor powered pump for times when the electricity goes out.

For an above ground effluent storage system, a slurry stirrer will also need to be considered. If you have electricity running to the site, there’s the option of an electric stirrer on top of a pedistall, or a through-the-wall electric slurry stirrer. If you prefer a PTO stirrer option, this is also available for through-the-wall, or you can get an extension to reach over the top of the tank.