Durability of Galvanising

Galvanised coating is better than paint in effluent equipment for a number of reasons. Zinc-iron alloy layers of hot-dipped galvanised (HDG) steel coating are durable in nature and have a rare need for maintenance, unlike field touch-ups that are required for painted bare steel.

Zinc Paint vs. Galvanising

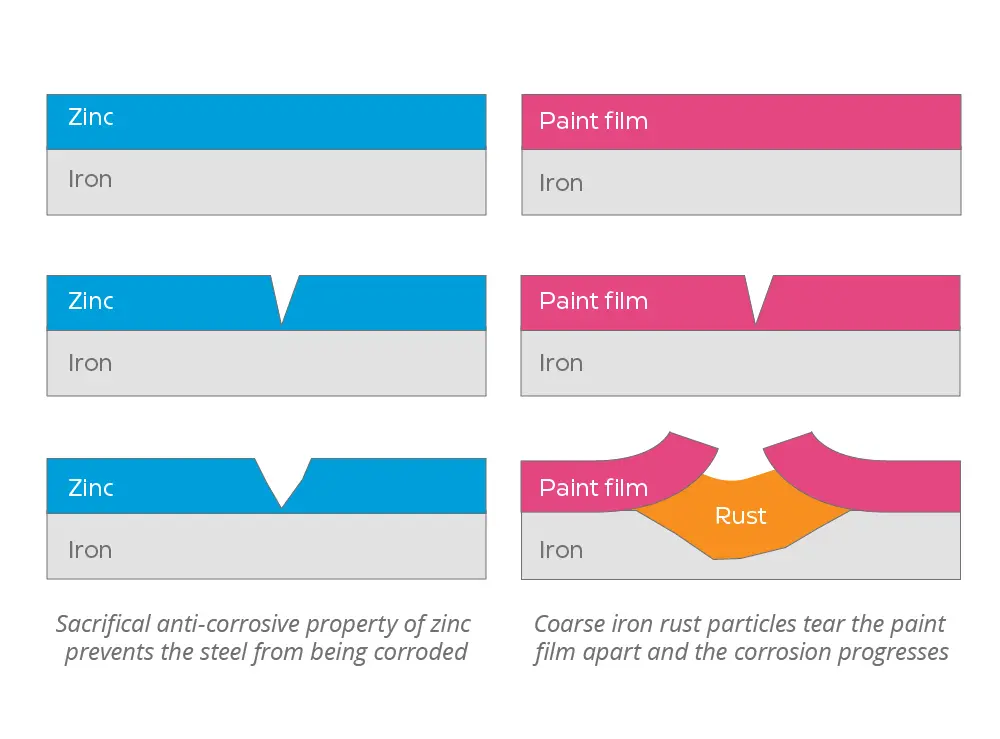

Paint often requires maintenance and is susceptible to environmental changes. If paint is scratched, it can create a reaction of corrosion that may not be noticeable at first. For instance, by the time you notice a bubble that is forming underneath the paint surface, rust will have already formed and compromised the integrity of the equipment.

Galvanised steel coating offers precise manufacturing that gives complete coverage. The alloying of zinc and iron in the coating creates a bond ten times greater than other mechanical bonds of paint to steel. The coating hardness acts as a cathodic and barrier protection that ensures longevity of equipment.

Galvanising Protects Against Corrosion

Effluent is corrosive on its own, which is why corrosion protection is important for effluent equipment. When it comes to slurry tankers, effluent can sit for a period of time that could create issues if the tanker is not constructed of galvanised steel coating on the inside and outside.

If the equipment utilises zinc paint, it can prove to be a higher risk of corrosion and continual issues with maintenance needs. By choosing materials that are made to protect against corrosion, you can ensure your effluent management system runs without delay or equipment issues.

Longevity Of Equipment

Recently there has been a move towards utilising zinc rich paints. However, when compared to hot-dipped galvanising, it does not retain its integrity over time. If you are shifting the needs of your farm or upgrading to larger equipment, galvanised steel ensures a higher resale value of equipment that provides a return on investment.

If you are looking for how to choose the right effluent equipment to add to your farm, come talk with our team to find the right solution for your equipment requirements.