Raining on the parade

Farming can be cruel, you can never be complacent, because for every up there is going to be a down. There are just some things you can’t control, especially the weather, which has a nasty habit of ruining a good mood. Tom Middlebrook has had to put up with his fair share of bad weather. NSW had one of those weather spats in April 2025. Severe thunderstorms, heavy rainfall and flash flooding – it wasn’t a good month. And a lot of hard work got washed away.

The calm before the storm

Before that storm, Tom had a lot to smile about. He’d taken a big step toward sorting out his effluent management system, landing on a more efficient and profitable set-up, a winning combo of a new Nevada slurry tanker and TurboStirTM 7000 PTO pond stirrer.

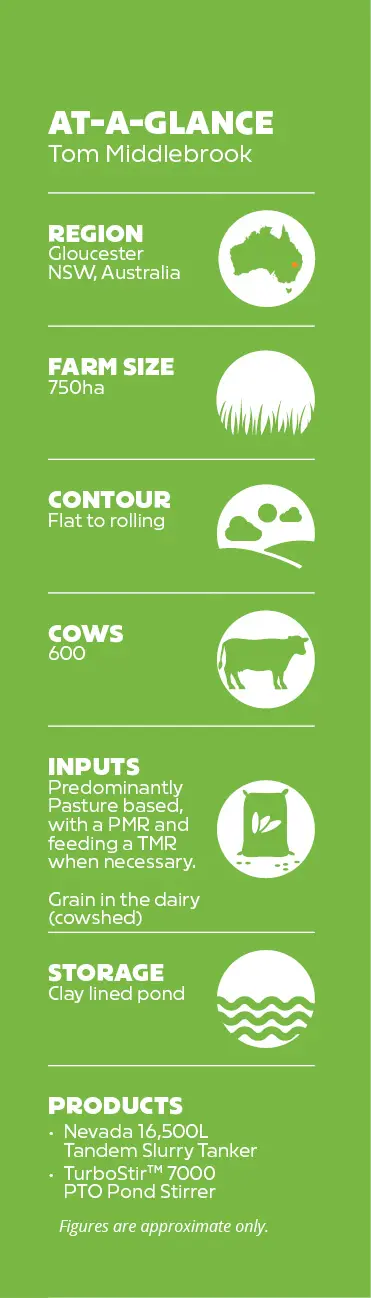

Tom milks six hundred cows every day of the year across two properties on Bowman Farm in Gloucester, NSW, Australia. Before the tanker, he was using a separation process, channelling the effluent into an underground concrete sump and then transferring it to an effluent dam using a corkscrew separator. This effluent was then pumped out to the surrounding paddocks using travelling irrigators.

In with the new, out with the old

But after twenty good years, this system was showing its age. The maintenance bills started to creep up, along with breakages and stoppages. The pumps struggled with the effluent, it wasn’t set and forget, there was always a problem to fix. And because the effluent was concentrated in just a few paddocks around the dairy, the soil was becoming saturated – not good for the soil or cows.

They had to find a better solution, something more efficient and that could make better use of the effluent those 600 cows produce every day. After some research, there was a clear winner, a combination of a 16,500 litre slurry tanker and PTO pond stirrer. The addition of the pond stirrer was a “non-negotiable” for Tom. It not only makes the suction process of the tanker much easier, it also creates a much more uniform, nutrient-rich product to spread over the paddocks.

Easy street

What he really likes is the fully galvanised tank; it is easy to operate and not a lot can go wrong. His tanker has steering axles and big flotation tyres, which make it easy to manoeuvre around the whole farm. But the single most impressive feature for him was the Duo RainWave™ applicators. He much preferred that over a splash plate applicator. He gets a nice even spread, no wind drift and less evaporation. The RainWave™ creates much larger drops that penetrate into the soil, so you can be much more accurate with your application.

Saved $18k in the first two months

In the first two months Tom used the new tanker and stirrer, he could see clear benefits. For a start, they were able to massively extend where they could deliver the slurry to the dairy farm. With the travelling irrigators, he would cover roughly 20 hectares of land. That has changed significantly – he now covers 200 hectares, improving soil health right across the farm. But more importantly, in just the first two months of use, he has saved eighteen thousand dollars on purchased nitrogen costs.

They were on easy street, they just had to hook the tanker up, fill her up in minutes and get stuck into spreading. They had a great working system with very little to go wrong, until the rains came.

After the rain

71.8mm of rain fell in April and, according to Tom, most of that ended up on his farm. His land was flooded, the tractor broke down, and feed costs went up. It wasn’t a good time, but like most farmers, Tom knew he would just have to work through until better times came around. What was hugely satisfying was the knowledge that he had a system in place that would be up and running the moment the weather allowed. Farmers might get knocked down, but they never get knocked out.