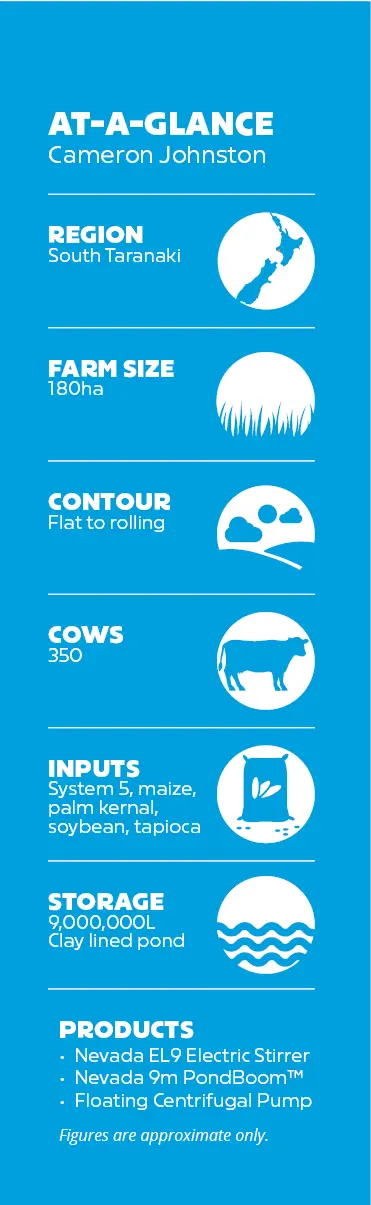

Cameron’s new dairy effluent system consists of a feed-pad, a clay lined storage pond, a 9 metre Nevada PondBoom PB900, a Yardmaster pump, and a 9 metre Nevada Electric Stirrer EL915. His brand new feed-pad operates on System Four inputs. 20-30% consists of maize, palm kernel, soybean and tapioca, 70-80% of inputs is grass fed.

The choice to upgrade from a small sump to a clay lined 9 million diamond-shaped pond was due to his previous system wasting valuable farm resources. They had no storage, so the dairy effluent was pumped from the small sump using a yardmaster pump straight to a travelling irrigator. If there was a breakdown, then they couldn’t operate; they had to stop milking to go and fix it. Otherwise the small sump would flood all the way back, which was a big issue for them, and for Fonterra.

One of the benefits of his dairy farm location being in Hawera is that Cameron was able to choose a clay lined pond. The good clay means there is no need to line the pond any further.

Nevada PondBoom™ – the ability to set and go

Cameron’s main benefit with his 9 metre Nevada PondBoom™ is the ability to set and go. He wanted something that didn’t require backing a tractor in. According to Cameron, the Nevada PondBoom™ just made sense.

Cameron was also pleased with his new Yardmaster pump’s capacity to pump what they need with the new system, with all of the new feed-pads.

Nevada Electric Stirrer EL915 – ease of use

Cameron’s new 9 metre Nevada Electric Stirrer and it’s ability to mix his 9million litre pond comes down to the momentum of the horizontal thrust design. It also has the ability to rotate 360 degrees for maintenance, and he can adjust the height for better stirring. But Cameron’s main benefit he noticed is ease of use. He can set timers to run, and go, and stop when they’re supposed to, and the Nevada PondBoom™ and Nevada Stirrer combination gets a really good effluent spread on the paddock.

But why choose Nevada?

When researching what type of sheds to build Cameron saw a lot of Nevada products. He also liked dealing with a local company as his family has enjoyed dealing with Nevada (previously MidWest Machinery) for years. .

Cameron is confident that his investment will future proof his farm for future expansion.

‘Everything we’ve done is to future proof. You never know what is going to happen in 10-20 years. We wanted to put something in that if the opportunity came to increase, or if we wanted to make big changes again, we would be able to. Everything is set to carry on a long time.’

Cameron Johnston – Dairy Farmer, Taranaki