Remove stones and sand

In order for a bladder tank to run effectively, it needs to have the sand, stones and grit removed from the effluent stream before it reaches the tank. Utilising stone traps are a vital part of an effective effluent system to remove any grit that may interfere with the drainage of the bladder.

If a few stones and grit do manage to enter the effluent bladder, there are solutions to removing them without causing issues with the storage capacity. Bladder tanks are able to manage some heavy solids when stirred into suspension. With adequate mixing, heavy solids are able to be pumped out the same way it entered the tank.

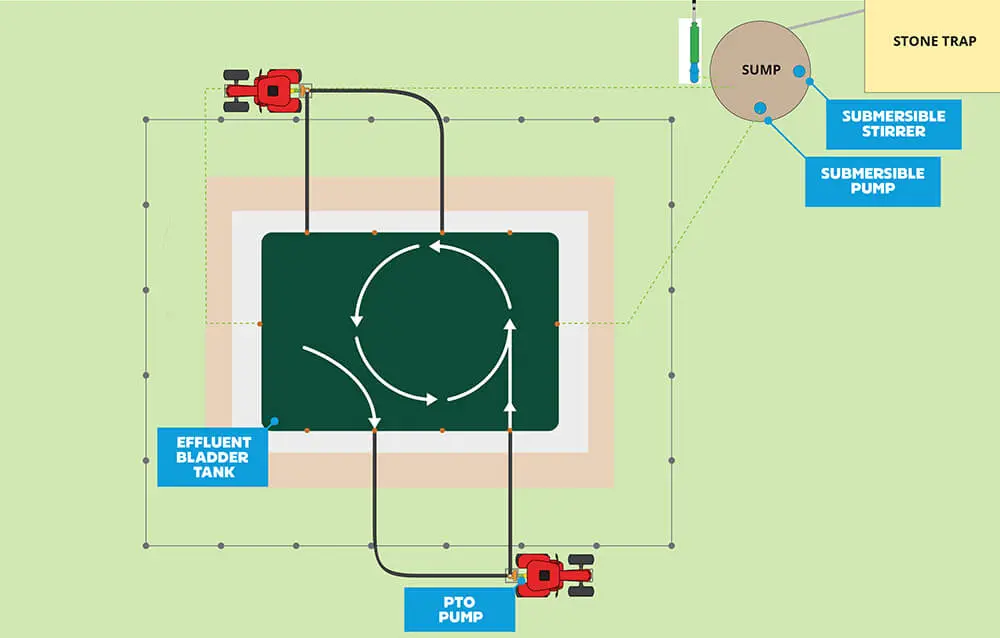

Stir with the multiple ports

It is critical that the bladder tank is thoroughly stirred before sucking any fluid out and irrigating out to the paddocks. Bringing the effluent into suspension helps avoid heavy sediment building up on the base of the bladder and over time making it difficult to mix in the future. Nevada bladder tanks are designed with a flat bottom and include multiple ports around the edges that are easily accessed.

To adequately stir the tank, utilise the ports around the bladder by sucking effluent out through one port and pumping it back into the bladder through another port with a high-volume effluent pump. This will create a swirling motion that brings it all into suspension. Switch to the opposite side to work around the different ports to make sure the tank is adequately stirred before irrigating.

On average, a bladder tank should be mixed for a minimum of 30 minutes to an hour, two – three times per week, but it may take longer if the tank has been left stagnant for several months. We recommend stirring thoroughly every time before the tank is emptied or any fluid is sucked out

What type of bladder tank works best?

Some brands on the market have a central discharge port that is located lower than the rest of the tank, but this can cause issues with mixing and blockages with sediment collecting at the lowest point. It is best to have a flat bottom bladder tank where solids are not easily trapped anywhere on the base of the tank and that can work easily with a pump mixing system.

What type of pump is required for stirring?

There are many variations when designing an effluent bladder tank system. What type of pump is required depends on the size of bladder chosen, as well as the specific flow requirements for the irrigation system. Generally an irrigation pump is not adequate to handle effluent stirring as they are not high enough volume, which is why we recommend using a high-volume PTO effluent pump. If a PTO effluent pump is not available, then a very large capacity motorised trash pump could be an option.

Chat with us about your specific needs for effluent storage and stirring

Designing an effluent system for your dairy farm takes careful consideration for the size of tank and the specific pumping requirements to manage flow for irrigation. Chat with our team today to learn more about how your dairy farm can run efficiently and reliably for a long time with the right effluent management system.