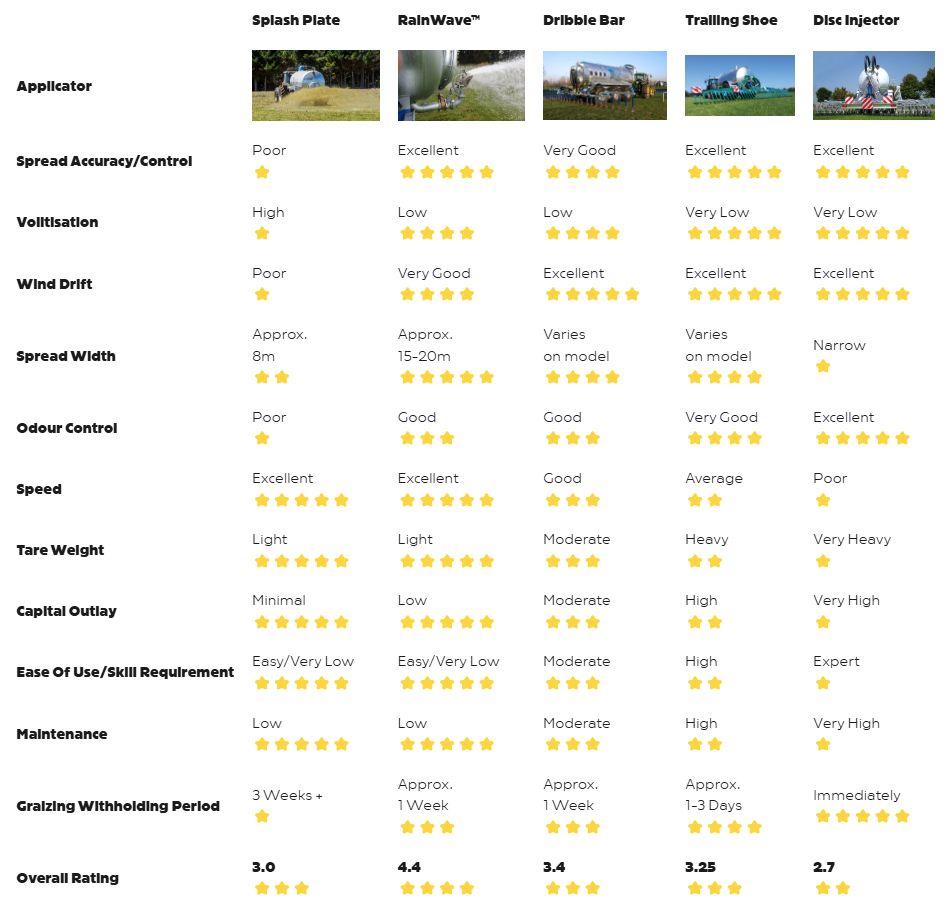

One of the key components of your slurry tanker is the spreading applicator. Where traditionally a splash plate was common place, many dairy farmers now recognise the benefits of more modern applicators, such as a RainWave™, Dribble Bar, Trailing Shoe or Disc Injector unit.

Below we’ve rated these different slurry tanker applicators based on 12 factors. The overall rating at the bottom is based on their average score.

1 Rainwave™

⭐⭐⭐⭐ 4.4

The Rainwave™ is a unique low pressure applicator. It has all the benefits of a dribble bar as well as being lower cost, lighter tare weight, and requires less maintenance and skill to operate. Independent tests prove the volitisation rate of a Rainwave™ is the same as a dribble bar.

2 Dribble Bar

⭐⭐⭐ 3.4

Dribble bars are relatively easy to operate, and provide accurate effluent application with very little volitisation and virtually no wind drift due to their proximity to the ground. However as the effluent is placed in evenly spaced bands, this can lead to hot spots upon application which is not favoured by councils. They require hydraulic functionality, moderate maintenance, and are relatively high in capital outlay.

3 Trailing Shoe

⭐⭐⭐ 3.25

Trailing shoes are recommended for areas close to urban life, where odour control is critical. They have significantly less odour than other applicators due to effluent being placed below crop foliage. This means there is virtually no volitisation or wind drift, and no crop spoiling. However trailing shoes do have a high capital cost as well as requiring high maintenance and operational skills. With a heavier tare weight and hydraulic operation, there are also specific tractor requirements to operate.

4 Splash Plate

⭐⭐⭐ 3.0

Splash plates are the cheapest, and most traditional slurry tanker applicator. Today, they are largely superceded by other, better methods of spreading. Although they are low cost, fast and require very little skill to operate, they are also inaccurate in their application, and have high volitisation rates. In some European countries, splash plate applicators are banned by councils.

5 Disc Injector

⭐⭐ 2.7

Disc injectors are the best form of odour control due to the effluent being injected directly into the soil. This also means cows are able to return to graizing almost immeditately, and there is no volitisation or wind drift. However these benefits come at a cost. Injecting directly into the soil runs the risk of leeching. They are also by far the most expensive option with a very high capital outlay, significant maintenance & operator skill requirements, and they are slow – so it will take longer to get the job done.