Galvanised steel lasts at least 5x longer than zinc paint as we’ll explain below. If you’re a farmer who wants to make smart choices, which if you’re reading this, we assume you are – GO GALVANISED. It really is the feature you can’t afford not to have – here’s why…

1. It’s More cost effective

We’re putting this point first, because it’s commonly thought that galvanising will cost more which can turn the more frugal investor off. Not only is it a total myth that galvanising is more expensive, but as you will see it’s something you can’t afford not to have when it comes to slurry tankers.

There’s likely to be very little difference in the initial investment of a galvanised or painted slurry tanker. If there is, ask why, because it’s more likely to be due to other manufacturing differences.

Of course the initial investment is nothing when you’re comparing something that will last 10 years vs 50 years. Spreading the cost over the usable life of the tanker makes galvanised far more cost efficient. Even if you plan on upgrading in the future, a galvanised tanker will hold it’s value in terms of re-sale or trade-in.

2. Lasts 5x longer than zinc paint

Galvanising and zinc paint both use the same base theory when it comes to corrosion protection. A zinc barrier is used to protect the base metal. However, the significant difference in terms of corrosion performance, sustainability and lifespan is like comparing superglue to PVA.

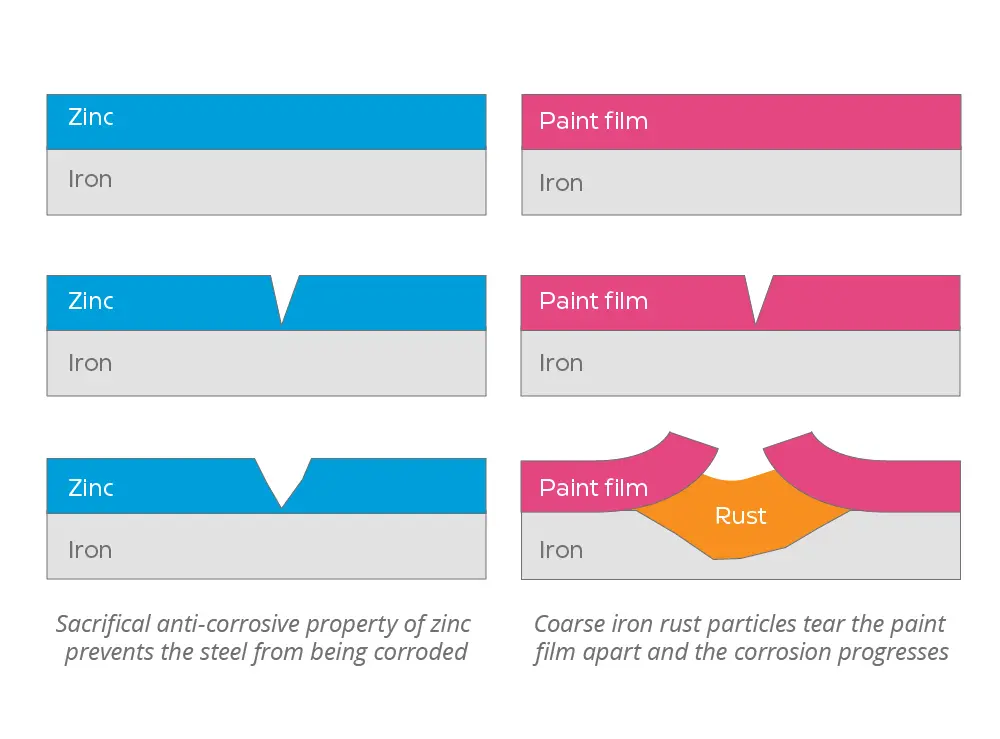

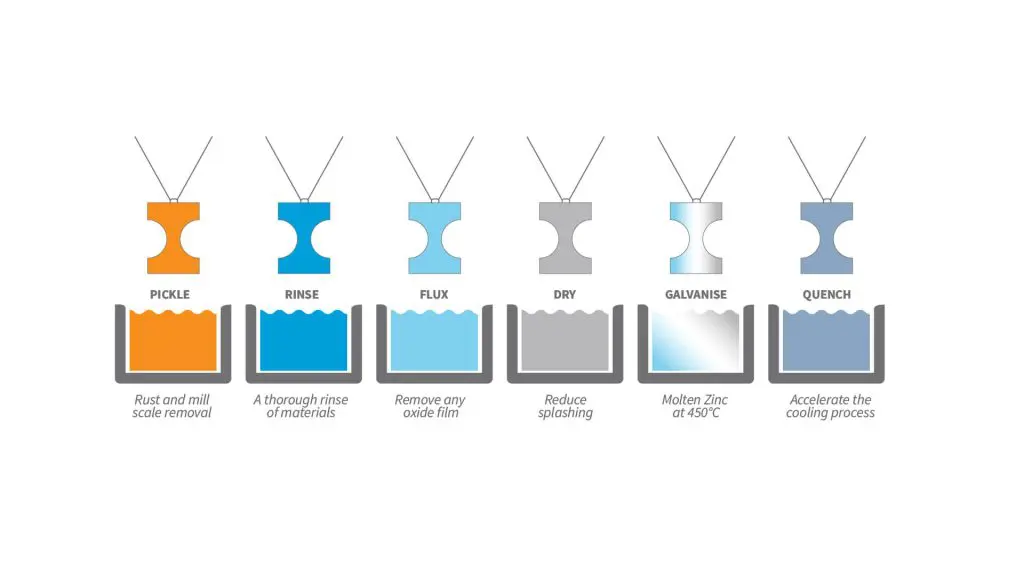

Galvanising has long been proven as the best form of corrosion protection, lasting 5x longer than zinc paint. Hot dip galvanising is a process where the steel is dipped into a bath of molten zinc, providing it with a permanent protective zinc coating. Even if the coating is scratched, the exposed steel is still protected by the remaining zinc.

Understandably, a painted surface can not be expected to live up to these performance standards. Unlike galvanisation, once the paint is scratched, the underlying metal is exposed and no longer protected from corrosion. Although the type of paint and standard of application will make a difference, paint is still far less durable in the harsh conditions inside and outside a slurry tanker.

3. Complete protection

Galvanising is the only way to provide corrosion protection over the entire tank, including the joints. The galvanising process is performed before the tank is put together, ensuring every crevice is protected. Galvanising does not require touch-ups.

Painting occurs after construction, so can only ever cover where the zinc paint will reach. A zinc painted slurry tanker will require regular checks and touch-ups to maintain the corrosive protection.

NOTE: It is critical your slurry tanker is protected both inside and outside the tank. Effluent is abrasive, so can corrode the inside of the tank, while the outside is susceptible to weather and other elements.

Is galvanising the best corrosion protection you can get for slurry tankers?

Yes and no. Galvanising can be taken one step further to provide the ultimate corrosion protection. After galvanisation, the outside is coated in a clear lacquer which further protects the galvanising itself. This is known as double corrosion protection. It not only adds to the lifespan of the tank, but keeps it in good condition and makes it easier to clean. In fact, it can be difficult to tell the difference between a 5- and 25-year-old slurry tanker!

Where here to help!

Contact one of our experts to find out more information on why Nevada Slurry Tankers are the right choice for your farm.