Slurry tankers in the 21st Century

Slurry tankers have evolved. Back in the day, they were slow, ponderous and dirty, but just like a modern hay baler, the difference is night and day. A modern slurry tanker is packed with technology that makes it easy and efficient to use, allowing you to safely and accurately spread effluent to over 90% of your farm, turning a waste by-product into a valuable resource.

Much easier to use

The slurry tanker that your dad would remember wasn’t pretty. It took an age to load, created a real mess and was very inefficient. Today, that slurry tanker is a completely different animal. It gives farmers the ability to quickly and easily spread effluent around their whole farm – no mess, no hassle. You can control everything from the cab of your tractor. It can help you meet your compliance needs, rejuvenate your soil and reduce the amount you are spending on synthetic fertiliser. Find out why farmers are turning to slurry tankers to deal with their effluent.

Galvanised Slurry Tankers

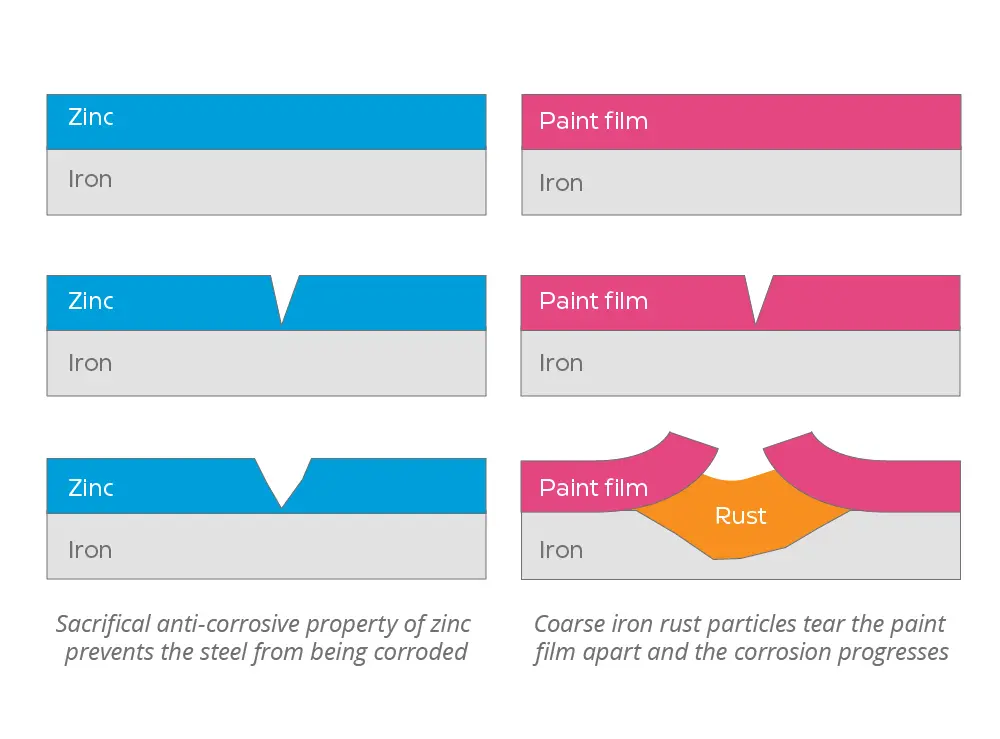

Nevada galvanised slurry tankers can haul anything from 6,150 to 43,000 litres of effluent. They are built to last – the zinc galvanisation gives exceptional corrosion resistance, durability and protection from the elements. The tank also uses a vacuum pump to load and unload the slurry, so less friction and much lower maintenance costs.

Pumping and Loading

No need to get out the cab, a big fat 8-inch auto-fill snorkel connects to your dam and sucks up the effluent. A 12,800L tanker will be filled in about three minutes and can unload that effluent in about the same time.

The tanker uses a 13,500-litre ballast air-injected vacuum pump to load and unload the effluent. Only air is going through the pump – no effluent, bits of wire or pebbles to mash the machinery. That means there are no fears of blockages, making them much more reliable than an irrigator, and they require less maintenance. The effluent is loaded at the front of the tank and pushed to the lowest point at the back. This prevents a build up of solids within the tank.

Spreading options

You have a wide array of applicator options to choose from, depending on what’s right for your farm. The most popular option is the RainWave™ applicator. This is a self-driven oscillating system, no hydraulic or electric drive necessary; it simply oscillates from side to side, giving you a perfectly even spread.

Pulling a tanker gives you a massive amount of control of when and where to spread. With a tanker you can reach every nook and cranny of your farm. The droplets from the RainWave™ are large, so they penetrate the foliage layer and reach the soil. This is better for nutrient uptake and improves soil health. With large droplets, there is virtually no wind drift or volatilisation of the nitrogen. Plus, minimal smell or odour, which your neighbours will thank you for.

Nevada tankers can be equipped with a Trailing Shoe or Disc Injector spreading methods – so the effluent is placed directly on the soil, allowing you to bring the herd back in sooner than with a traditional splash plate spreader.

If you have areas that can’t be reached by your tractor, like a steep slope or crop paddocks, a Nevada RainGun is a good option. This will give you range, but to use a RainGun, your tanker will also need to be fitted with a Garda Pump.

Environmental and efficiency benefits

You have much more control and precision with a slurry tanker. You can see exactly how much you are applying from the cab, so it is easy to back off and prevent run-off. Because of their manoeuvrability and precise application of the spreader, you can get much closer to your boundary, roads and waterways.

If your tractor has GPS you will know exactly where you’ve been, which will help you with compliance. It is very efficient to apply effluent to the paddock the cows have just grazed. The grass has the best chance of recovery if you spread effluent straight away and the easiest way to do that is with a slurry tanker. You have to move your cows anyway, so why not take the tanker with you and get two jobs done at once?

What sized tanker?

Picking the right sized tanker will depend on a few factors – the topography of your farms, how many cows you have, but primarily on the power of your tractor. As a rule of thumb, you’ll need one horsepower for every 100 litres of effluent. So a 10,000 litre tanker needs a 100 horsepower tractor and a 15,000 litre tanker needs a 150 horsepower tractor.

Whatever tanker you choose, they are all easy to manoeuvre. They are fitted with large flotation tyres to spread the load, so there is no damage to paddocks. There is suspension on the axles, suspension on the drawbar, brakes on all wheels and a steering axle on the rear wheel of the tandem and triple-axle tankers. Large internal baffles prevent surging. All this technology gives you an incredibly smooth ride, and makes the tanker very easy to use.

Smart investment

The 21st Century slurry tanker is a completely different beast to the one from days gone by. It is efficient; all you need is one tractor, one staff member. It is fast to load and to spread, saving you heaps of time and hassle. It is clean, no mess, you can do everything from the cab of the tractor. It gives you the ability to spread effluent over the whole farm, potentially saving you thousands of dollars on artificial fertiliser costs.

This is Scott Connell: find out what he thinks of his 10,000L tanker.

If you want to find out more or discuss which tanker would be right for your farm, give our sales team a call on 1800 963 490